Gear motors represent a ubiquitous and vital component in modern manufacturing, silently powering a vast array of machinery. Their ability to combine efficient power delivery with controlled speed and torque makes them indispensable for automating processes and enhancing overall productivity. This article delves into the fundamental principles of gear motors, analyzes their performance characteristics, and explores their diverse applications within the manufacturing landscape. We’ll examine the different types of gear motors, their advantages and disadvantages, and discuss emerging trends shaping their future.

Understanding the Core Principles of Gear Motors

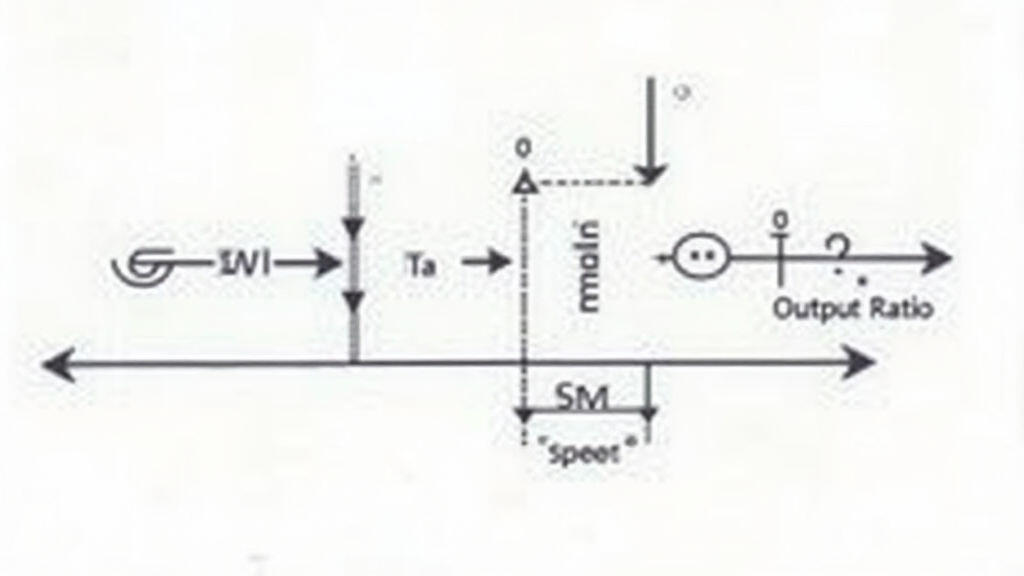

At its heart, a gear motor is a combination of a motor and a gear reducer. The motor provides the rotational power, while the gear reducer modifies that power by altering the speed and torque. This is achieved through a system of interlocking gears, each designed with a specific number of teeth. The ratio of teeth between the input (motor) and output (gear) gears determines the speed reduction and torque multiplication.

The basic principle is simple: rotating a smaller gear (input) drives a larger gear (output). This mechanical advantage increases the output torque while simultaneously reducing the output speed. Conversely, a smaller gear driving a smaller gear (resulting in a gear ratio less than 1) will increase output speed at the expense of decreased torque.

There are several common types of gears used in gear motors, each with its own strengths:

Spur Gears: These gears have straight teeth and are simple, efficient, and cost-effective. They are suitable for applications requiring high speeds and moderate loads.

Helical Gears: Helical gears have angled teeth, which offer smoother and quieter operation compared to spur gears. They are also capable of transmitting higher loads and are often used in high-power applications.

Bevel Gears: Bevel gears are used to transmit power between shafts that are at an angle to each other. They are commonly found in applications like power transmission systems and differentials.

Worm Gears: Worm gears utilize a worm (a screw-like gear) meshing with a worm wheel. They offer a very high gear ratio in a compact design, making them suitable for applications requiring substantial torque reduction and low speeds.

Performance Characteristics: A Deep Dive

The performance of a gear motor is characterized by several key factors:

Gear Ratio: This crucial parameter directly dictates the trade-off between speed and torque. A higher gear ratio means lower speed and higher torque.

Efficiency: Gear motors are not 100% efficient due to frictional losses within the gear system. Efficiency is a critical consideration, especially in energy-conscious manufacturing environments. Higher efficiency translates to lower operating costs and reduced heat generation.

Torque: The amount of rotational force the motor can produce, directly influenced by the gear ratio and motor power.

Speed: The rotational speed at the output shaft, determined by the gear ratio and motor speed.

Power Rating: The amount of power the motor can deliver, considering both torque and speed.

Backlash: A small amount of play or looseness in the gear mesh. Excessive backlash can lead to inaccuracies and vibration.

Durability & Reliability: The lifespan of the gear motor under continuous operation and varying loads. Lubrication, material selection, and design contribute to durability.

Applications in Manufacturing: A Wide Spectrum

Gear motors are essential in a diverse range of manufacturing applications, including:

Conveyor Systems: Gear motors power conveyor belts for transporting raw materials, work-in-progress, and finished goods.

Robotics: They provide precise control and power for robotic arms and actuators, enabling automated assembly and material handling.

Packaging Machinery: Gear motors drive filling, sealing, and labeling equipment in packaging lines.

Printing Presses: They provide the necessary speed and torque for printing mechanisms.

Material Handling Equipment: Forklifts, cranes, and other material handling equipment utilize gear motors for lifting and moving heavy loads.

Automated Assembly Lines: Gear motors control various stages of automated assembly, from component positioning to final product assembly.

Machine Tools: Gear motors are employed in lathes, milling machines, and other machine tools for precise positioning and motion control.

Emerging Trends and the Future of Gear Motors

Several trends are shaping the future of gear motor technology:

Miniaturization: Manufacturers are increasingly demanding smaller and lighter gear motors for space-constrained applications, particularly in robotics and portable equipment.

Higher Efficiency: Improved gear designs, precision manufacturing, and advanced lubrication techniques are leading to more efficient gear motors, reducing energy consumption and operating costs.

Smart Gear Motors: Integrating sensors, data logging, and connectivity features allows for predictive maintenance, performance monitoring, and remote control. This aligns with the Industrial Internet of Things (IIoT) and Industry 4.0 initiatives.

Materials Innovation: Development of new materials - including advanced polymers and composites - contribute to weight reduction, improved durability, and enhanced performance in demanding environments.

Integration with Electric Drives: Gear motors are increasingly being integrated with electric drives and variable frequency drives (VFDs) to provide precise speed control and improved energy efficiency.

Conclusion

Gear motors are cornerstones of modern manufacturing, facilitating automation, enhancing productivity, and enabling complex processes. Understanding their principles, performance characteristics, and diverse applications is critical for optimizing manufacturing operations. The ongoing trends of miniaturization, increased efficiency, and smart functionality are poised to further elevate the role of gear motors in the evolving manufacturing landscape. With the accelerating adoption of IIoT and Industry 4.0, gear motors with integrated sensors and connectivity will play an increasingly vital role in predictive maintenance, process optimization, and overall smart manufacturing ecosystems. As manufacturing continues towards greater automation and precision, the demand for reliable, efficient, and intelligent gear motor solutions will only intensify, making it a vital area of ongoing innovation.

Leave A Reply

Your email address will not be published. Required fiels are marked